Electrical Overload

Air suspension systems rely on different components compared to standard hydraulic systems. To be more specific, they rely on compressors, solenoids and valve blocks - all of which draw significant electrical current, placing added stress on relays and fuses. Over time, this will eventually lead to overheating, blown fuses and premature relay failure. For this reason, cars with air suspension are usually in need of contant TLC, with electricians chasing down persistant and almost impossible-to-repair electrical faults. Not only does this cost the owner a fortune, but it is also a lot of work for the repair shop.

Sensor Failures

When it comes to air suspension, height and pressure sensors are essentially the 'eyes' of the system, as they relay information to the ECU, letting it know just how high or low the car sits. However, these sensors are constantly exposed to dirt, grime, moisture and vibration, meaning that they are more than likely to experience a few issues over time. The biggest problem with this is the fact that a single faulty sensor can cause the entire system to go into limp mode, making the car almost impossible to drive.

Control Module Costs

The ECU (Electronic Contol Unit) is the brain of an air suspension system. If it fails, the car will lose all ability to self-level or adjust its ride height, which is obviously a major problem. However, many owners can't afford to buy a new ECU, as they are incredibly expensive. In fact, it costs more than double the price of a traditional suspension replacement. Programming is also required, adding to the cost and complexity of the repair. Overall, the cost of the control module is enough for electricians to advise against buying a vehicle with air suspension.

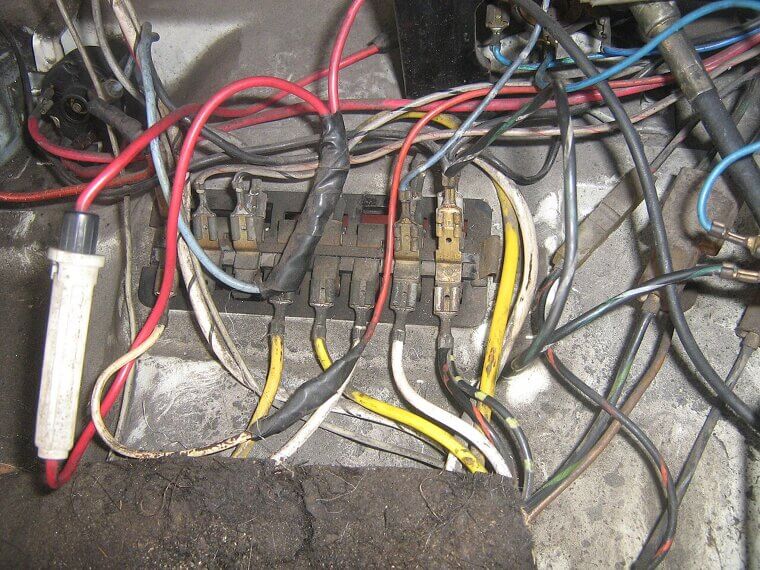

Complex Wiring Harnesses

Compared to regular suspension systems, air suspension requires additional wiring to connect compressors, valves, sensors and, of course, the ECU itself. Oftentimes, these wires pass through areas exposed to debris, heat and moisture, making them prone to damage. In fact, electricians are often faced with repair jobs in which they have to replace corroded or broken wires. Short circuits are also incredibly common and can be tricker to not only repair, but also locate.

Moisture Intrusion

The electrical connectors in an air suspension system are usually located near the wheel wells or under the car itself. As a result, they are often exposed to rain, mud and road salt, all of which lead to corrosion. In fact, even the smallest amount of moisture can lead to massive electrical faults that are notoriously difficult to diagnose. More so, any fault in an electrical connector will cost a small fortune to repair. However, there is simply nowhere else for them to go.

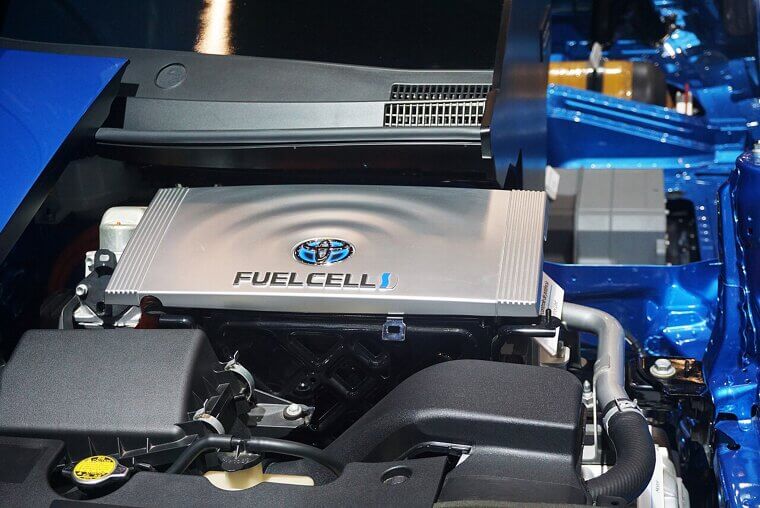

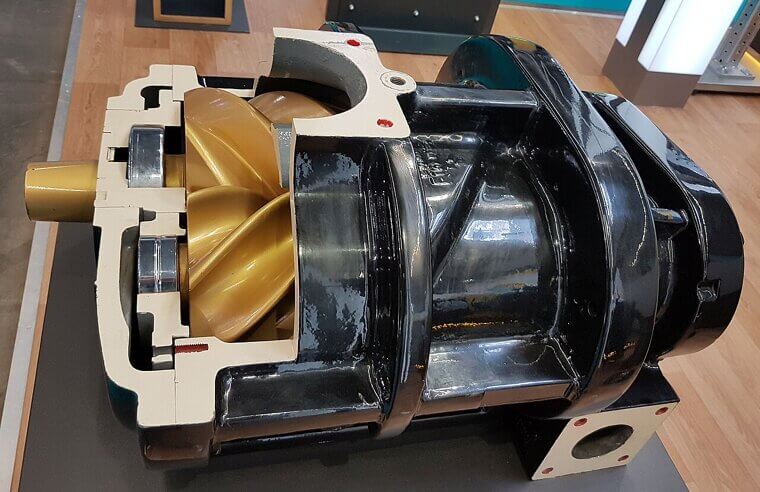

Compressor Burnout

The compressory is essentially tasked with with electrically maintaining air pressure in the system. Any issue (even a minor leak) with this component can be catastrophic, causing the car to drop to the ground and leaving the driver stranded on the side of the road. Another common issue with the compressor is overheating. It runs constantly, meaning that the system will eventually become overworked and seize - especially if you often use the car for long trips. In this case, it could cost thousands to have the system repaired.

Diagnostic Headaches

Unlike regular suspension systems, air suspension requires specialized diagnostic tools to pick up any sort of fault codes. However, not all auto repair shops actually have these systems, as air suspension vehicles aren't overly common. The ones who do, however, find these systems incredibly frustrating to work with, as faults can be incredibly tricky to pick up on. Electricians often say that even the simplest of fixes are a mission with air suspension vehicles, as they simply can't figure out what the problem is!

Chain Reaction Faults

It's important to note that all the components of an air suspension system are connected, meaning that a single fault can result in a whole array of problems. In fact, even the smallest of issues, such as a slightly worn down wire, can cause the entire car to be uneven or completely immobile. Electricians often recommend against air suspension cars for this one particular reason. After all, nobody wants to be driving a car where one small fault can lead to a major breakdown. Not only is it inconvenient, but it can also cause bad driving anxiety.

Unreliable Aftermarket Electronics

The components of an air suspension system are generally more expensive than that of a regular system. Because people don't want to spend thousands on repairs every year, they often turn to aftermarket sensors or modules. However, these parts are usually less durable and tend to fail sooner, meaning that owners end up replacing them multiple times and spending just as much as they would have to buy the new part in the first place.

High Repair Costs

When it comes to traditional suspension systems, repairs are pretty straight-forward. In face, simple coil or leaf spring replacements can be fixed within a day for very little cost. The same can't be said for air suspension systems. Even the most basic of components are specialized, meaning that they cost a small fortune. Labor is also intensive, only adding to the overall cost of owning such a vehicle. Electricians know that owning such a car means constant, costly repairs - which is exactly why they recommend against it.