Nobody Uses These One-Widespread Automotive Tools Anymore

These lost tools, which ranged from tire bead breakers to timing lights, used to dominate garages. They helped create a manual automobile maintenance period that has since been supplanted by quiet efficiency and digital diagnostics. Continue reading for 15 vintage automotive tools that have gone out of fashion.

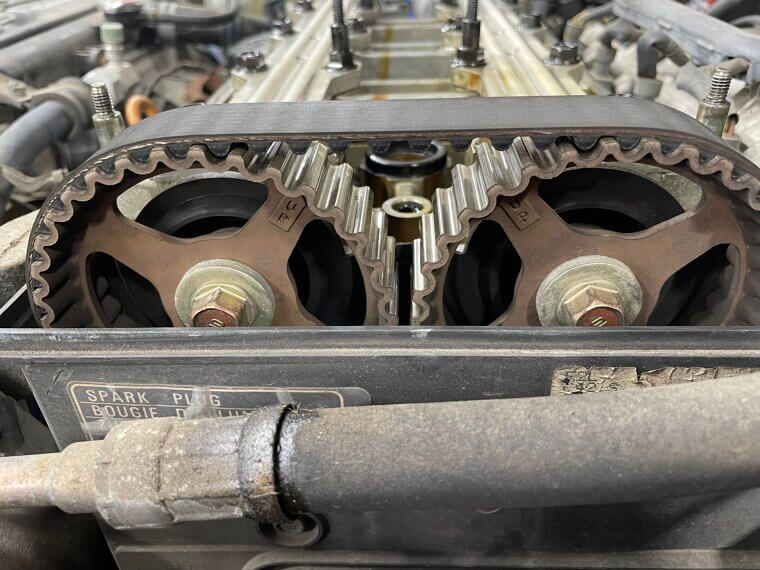

Spark-Plug Gap Tool

Prior to pre-gapped plugs becoming commonplace, this small device was a garage necessity. It was employed by mechanics to measure and modify the spark plug gap for the best possible ignition. These days, factory accuracy and plugs that hardly ever require adjustment have mostly replaced it, making it a drawer antique.

Dwell Meter

The dwell meter was essential for adjusting breaker-point ignitions, as its job was to measure the duration of a coil's electrified state. This once-essential device quickly became obsolete as electronic ignitions took its place. Those who could interpret needle swings like a second language are now the ones who remember it the most!

Distributor Wrench

This unusual-looking wrench was designed to access the distributor hold-down bolt in small engine compartments. Sure, it spared curses and knuckles, but the clever bend of this instrument is now more nostalgic than required because distributors are no longer used in modern engines.

Pre-OBDII Diagnostic Scan Tools

Before ports and codes were standardized, mechanics had to decipher obscure signals using brand-specific scan instruments. Every car spoke a language of its own! However, the universal language used by today's OBDII systems renders these cumbersome.

Engine Analyzer

This multipurpose wonder examined everything from cylinder balance to ignition timing - it took a great deal of expertise, especially as it resembled a spaceship control panel. The analyzer is now left to collect dust in aging garages as onboard computers and small digital gadgets complete the task more quickly.

Most Pneumatic Tools

The shop floor used to be dominated by loud, strong, and heavy compressor-tethered air-powered tools. But nowadays, battery technology has altered everything. With the mobility and precision that cordless electric tools provide today, most pneumatic equipment seems unnecessary, unless you're restoring vintage items.

Split-Rim Tire Tools

Split-rim wheels, which were mostly on trucks and farm equipment, were serviced using these powerful tools. But their usefulness only went so far - they had a reputation for causing severe injuries and were deadly if handled improperly (which led to their extinction.)

Babbitt Bearing Molds

Babbitt bearings were made by mechanics pouring molten metal into molds prior to the invention of modern bearings. It was a laborious and skillful procedure that required both patience and accuracy. These molds are now considered museum artifacts of mechanical skill since pre-made bearings are safer, cleaner, and more dependable.

Distributor Machine

Distributors were calibrated and tested outside the vehicle using this benchtop instrument; it spun them at speed to check advance curves and point function. The machine, which is now a curiosity for antique racers and restoration purists, vanished along with the distributors.

Timing Light (Standalone)

Timing lights were used to manually set ignition timing by flashing a strobe at the crank pulley. They were indispensable when it came to tuning older engines. These lights, however, are mostly boxed away—relics of a manual, trial-and-error era—as computer-controlled timing is now the norm.

Manual Tire Bead Breaker

It took brute force and leverage to shatter a tire bead before the advent of automated machinery. This tool assisted in separating the tire from the rim, often with a satisfying thud! However, modern tire changers now complete the task in a matter of seconds, rendering this tool largely obsolete.

Hand-Crank Oil Extractor

This pump-style instrument was slow, messy, and frequently frustrating as it extracted oil through a tiny dipstick tube. Thankfully, electric extractors and gravity drains replaced it with faster, cleaner techniques. The crank is still remembered with a mixture of nostalgia and greasy palms by some do-it-yourselfers.

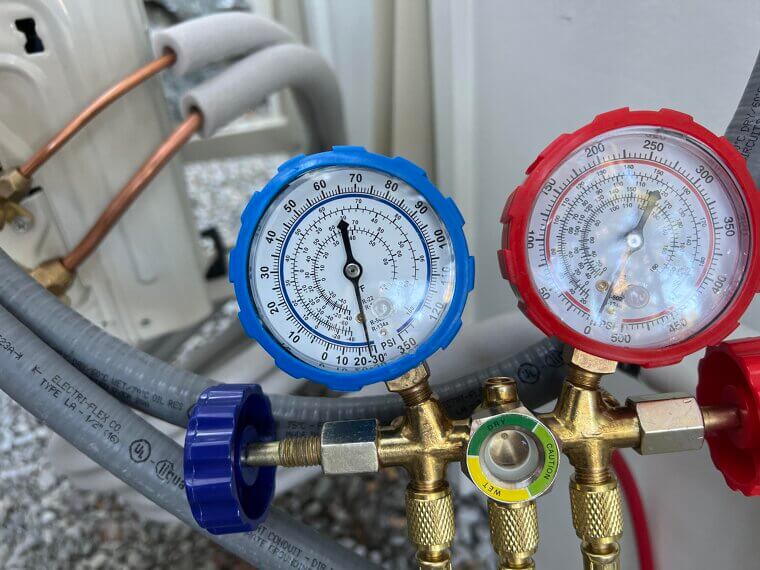

Vacuum Gauge

The vacuum gauge was a diagnostic mainstay that used needle behavior to determine engine health. Interpreting the readings required skill - much like mechanics reading tea leaves. This analog gauge is now left to the vintage tool crowd as digital tools perform the task more accurately.

Radiator Pressure Tester (Analog Bulb Type)

This rubber-bulb tester pressurized the cooling system to check for leaks; it was a simple yet efficient method. These days, the bulb-style gadget is a throwback to a time when cooling systems were more interactive, as sealed systems and digital tests have rendered it obsolete.

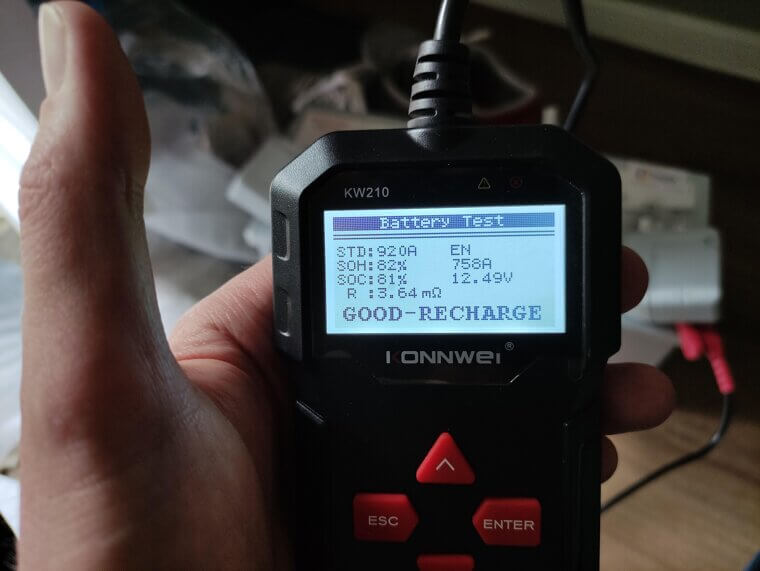

Carbon Pile Battery Tester

This beast applied a heavy load to test battery strength, often with dramatic sparks and heat. Yes, it worked, but it was also dangerous. The carbon pile tester is a holdover from the "test it 'til it smokes" era; conductance testers nowadays are much safer.