Ford F-250's Legendary Durability

The Ford F-250 earned its reputation one hard day at a time. These trucks rolled off assembly lines from the 1960s through the 1990s with one job in mind: hauling heavy loads without complaint. The inline-six and V8 engines were built with thick cast-iron blocks that could take abuse year after year. You'd see them on construction sites, farms, and ranch roads where pavement was just a memory. What made them special was how little they asked from you. Change the oil, keep coolant in the radiator, and they'd run another decade. Many still do. Owners report odometers rolling past 300,000 miles on original engines. That kind of durability wasn't an accident. Ford used heavier frame rails and beefier suspension components than the half-ton models, which meant these trucks could handle punishment that would bend lighter frames.

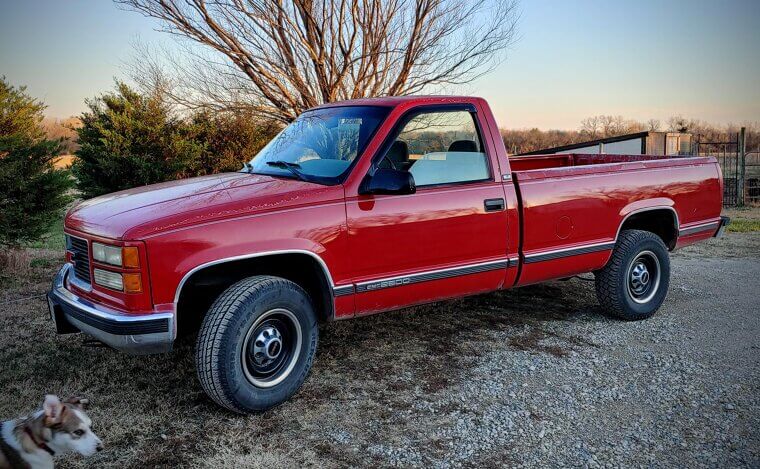

Chevy C20's Unstoppable Work Ethic

The Chevy C20 showed up for work every single day. From the late 1960s through 1987, these trucks carried everything from lumber to livestock without breaking a sweat. The small-block Chevy engine under the hood became legendary for a reason. Mechanics could rebuild them blindfolded, and parts were everywhere. You didn't need a computer or special tools to keep one running. Just basic hand tools and common sense. The C20 had a wider stance than lighter trucks, which made it stable when loaded down. Farmers loved them because they could pull a loaded trailer through mud and keep going. The cab was basic, sure, but that meant fewer things to break. No power windows to fail, no electronic modules to short out. Just a truck that started every morning and did exactly what you asked it to do.

Dodge D200's Heavy-Duty Heritage

Dodge built the D200 for people who needed more than a light-duty truck could deliver. These machines came with heavy-duty rear axles and suspension setups designed for serious weight. The slant-six engine option was nearly indestructible, known for running even when neglected. Dodge used thicker metal in the bed and reinforced the frame to handle commercial use. You'd find these trucks at construction companies, utility services, and ranches where breakdowns cost real money. The steering was manual and took some muscle, but it gave you direct feedback about what the wheels were doing. That mattered when you were backing up to a trailer or navigating rough terrain. Many D200s are still earning their keep today, decades after they were supposed to wear out. The secret was overbuilt components that had more capacity than most owners ever needed.

GMC Sierra's Rugged Reliability

GMC marketed the Sierra as the upscale option, but underneath it shared the same tough bones as the Chevy C20. The difference was in the trim and details. You got a nicer interior, better sound insulation, and chrome accents that made it look sharp at the job site. But the real story was what you couldn't see. GMC used the same proven drivetrain and frame that made these three-quarter-ton trucks nearly bulletproof. The 350 V8 delivered plenty of torque for towing without feeling strained. Owners appreciated how smooth these trucks rode even when empty, thanks to better shock absorbers and suspension tuning. Many Sierra models came with dual fuel tanks, which meant you could work all day without hunting for a gas station. That practical thinking showed up everywhere on these trucks, from the simple gauge cluster to the heavy-duty alternator.

International Harvester's Farm Legacy

International Harvester built farm equipment before they built trucks, and it showed. The Travelette and other three-quarter-ton models were designed by people who understood what farmers actually needed. These trucks featured extra-low gearing for pulling stumps and moving heavy equipment at slow speeds. The cabs were tall and roomy because farmers spent long hours behind the wheel. International used their own engines, which were related to their tractor motors. That meant incredible low-end torque and the ability to lug heavy loads without downshifting constantly. Parts were available at farm equipment dealers, not just auto parts stores. When you needed something fixed, the local IH dealer usually had what you needed. These trucks weren't fancy, but they were honest. They'd pull a loaded grain wagon through a muddy field and then drive you to church on Sunday.

The Toyota That Surprised Everyone

Toyota's heavier pickups arrived in America during the late 1970s and caught domestic truck owners off guard. Japanese engineering meant tight tolerances and quality control that American manufacturers hadn't matched yet. The diesel engine option delivered incredible fuel economy for a truck that could compete with three-quarter-ton hauling demands. These pickups used a ladder frame similar to domestic trucks but with better rust protection from the factory. The manual transmission shifted cleanly, and the clutch could handle abuse without slipping. What really stood out was how little maintenance they required. Oil changes and basic service kept them running for hundreds of thousands of miles. The ride was stiffer than American trucks, but that meant less body roll when loaded. Many commercial users switched to Toyota after one lasted twice as long as the domestic truck it replaced. That reputation for reliability made them expensive on the used market even today.

Why Square Bodies Became Icons

The square body Chevy and GMC trucks from 1973 to 1987 didn't just work hard. They became the most recognizable truck shape in American history. That flat, angular design gave them a look that still turns heads at car shows and cruise nights. But the real reason they lasted is the aftermarket. You can still buy nearly every part new today, from weatherstripping to complete frame sections to reproduction sheet metal. Try doing that with most trucks from the same era. The boxy panels were easy to repair and cheap to replace, which kept them on the road long after curvier designs rusted out in junkyards. Visibility was another advantage. Upright windshields and big windows meant you could see all four corners when parking or backing a trailer. These trucks proved that sometimes the simplest design is the one that ages best.

The 7.3 Diesel That Wouldn't Quit

When Ford dropped the 7.3-liter diesel into the F-250 in the late 1980s, they created something that bordered on immortal. The naturally aspirated IDI version was slow but almost impossible to kill. Then the Power Stroke turbodiesel arrived in 1994 and gave it real power to match that durability. These engines became the gold standard for anyone who towed heavy loads for a living. Contractors, horse trailer owners, and fifth-wheel campers all swore by them. The mechanical simplicity of the earlier IDI motors meant shade-tree mechanics could work on them without a laptop. Even the later Power Strokes were straightforward compared to the electronics-heavy diesels that came after. Used 7.3 trucks now sell for more than they cost new in some cases. That tells you everything about how much people trust that engine.

Chevy K20 Owned the Off-Road

The K20 was everything the C20 was, plus four-wheel drive and the attitude to use it. Chevy's transfer case and front axle setup gave these trucks real off-road ability without sacrificing much on pavement. Ranchers in Montana, loggers in Oregon, and plow drivers across the Midwest all depended on K20s to get through conditions that stopped two-wheel-drive trucks cold. The Dana 44 front axle was tough enough for trail use, and the full-floating rear axle handled heavy loads without complaint. What set the K20 apart from lighter four-wheel-drive trucks was its payload. You could load the bed, hook up a trailer, and still crawl through a muddy back road without spinning your wheels. These trucks didn't care about weather or road conditions. They just went where you pointed them and pulled whatever you hitched to the back.

The Original Dodge Power Wagon

Before "Power Wagon" became a trim package on a modern Ram, it was a standalone truck with a military pedigree. Dodge based the original on their World War II military trucks and started selling them to civilians in 1946. By the time the name carried into the 1960s and 1970s three-quarter-ton models, it meant something specific: a truck built for the worst roads and heaviest loads. Power Wagons came with heavy-duty axles, a low-range transfer case, and a winch option that made them a one-truck rescue operation. Utility companies and rural fire departments bought them because nothing else could reach the places they needed to go. The name carried weight because the truck earned it over decades of proving itself in conditions that broke other machines. You don't last that long on reputation alone.

Ford's Ranger Trim Before the Name Split

Before the Ford Ranger became its own compact truck in the 1980s, "Ranger" was a trim level on the full-size F-series. The F-250 Ranger package from the 1970s gave you a nicer interior and better exterior trim on the same heavy-duty platform. You got woodgrain dash accents, upgraded seat fabric, and chrome bumpers that dressed up what was still a serious work truck underneath. A lot of buyers chose this package because they wanted one vehicle that could haul during the week and look presentable on the weekend. It was a smart move by Ford — they figured out early that some truck buyers didn't want their ride looking like a fleet vehicle. The Ranger-trimmed F-250s are collector favorites now because they combined that three-quarter-ton backbone with a level of finish most work trucks never offered.

Jeep's J-Series Trucks Meant Business

Most people think of Jeep as an SUV brand, but they built some of the toughest pickup trucks on the road from the 1960s through 1988. The J-series, including the Gladiator and later the J-10 and J-20, came with the same four-wheel-drive systems that made Jeep famous. The J-20 was the three-quarter-ton option, and it could handle loads that surprised people who underestimated it based on the Jeep name. AMC's 360 V8 provided solid towing power, and the truck's shorter wheelbase made it more nimble than the Big Three's offerings in tight spaces. These trucks found loyal buyers among people who needed off-road ability and hauling capacity in one package. Production numbers were low compared to Ford and Chevy, which makes surviving examples rare and increasingly sought after by collectors who know what they've got.

Built for Work, Not for Show

There's a reason these three-quarter-ton trucks keep showing up decades after they were supposed to be scrapped. They were built with thicker frames, heavier axles, and bigger brakes than anything in the half-ton lineup. That extra capacity meant they spent most of their lives working well under their limits, which is why so many survived. Modern trucks have more horsepower, better fuel economy, and nicer interiors. Nobody argues that. But the older three-quarter-tons had something harder to measure. They were simple enough that anyone with a basic toolbox could keep them running. Parts were affordable and available at any auto parts counter in the country. And they were built during an era when overengineering wasn't a dirty word. If you've still got one in your driveway or know someone who does, you already understand why they refuse to die.